Research

Physical Properties of Tyre Walls, The University of South Australia

In 2017, Dr Freney secured funding of over $100,000 from Tyre Stewardship Australia to do a study of tyre walls in terms of their strength and resilience as retaining walls in Earthship homes, especially regarding their behaviour during an earthquake. Tyre Stewardship Australia is a government agency with the aim of dealing with the 55 million waste car tyres Australians produce every year - in an ecological and sustainable way!

55 thousand Earthship homes could be built in Australia every year with the 55 million waste tyres that we Aussies generate each year!

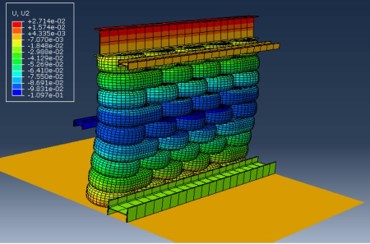

The research is underway at The University of South Australia by a team of structural engineers. The video above shows some terrific world-class research by the team* of just how resilient tyre walls are!

This wall is built in the usual Earthship way - the tyres are lined with cardboard, filled with earth, and then the earth is compacted until the rims of the tyre swell up.

A hydraulic ram is pushing sideways in the middle of the wall to simulate loads on the wall during an earthquake while another ram pushed down on top of the wall to simulate the weight of a roof.

Any "normal" wall would crack and be permanently damaged... not this wall!

The testing indicates that Earthships would perform well in earthquakes and many of the engineering methods used in Earthships to reinforce the walls could be scaled back due to the inherent strength and resilience of the tyre walls.

(*PhD candidate Yachong Xu, Principle Supervisor Associate Professor Yan Zhuge, Co-supervisors Dr Reza Hassanli, Dr Mizanur Rahman & Dr Martin Freney)

55 thousand Earthship homes could be built in Australia every year with the 55 million waste tyres that we Aussies generate each year!

The research is underway at The University of South Australia by a team of structural engineers. The video above shows some terrific world-class research by the team* of just how resilient tyre walls are!

This wall is built in the usual Earthship way - the tyres are lined with cardboard, filled with earth, and then the earth is compacted until the rims of the tyre swell up.

A hydraulic ram is pushing sideways in the middle of the wall to simulate loads on the wall during an earthquake while another ram pushed down on top of the wall to simulate the weight of a roof.

Any "normal" wall would crack and be permanently damaged... not this wall!

The testing indicates that Earthships would perform well in earthquakes and many of the engineering methods used in Earthships to reinforce the walls could be scaled back due to the inherent strength and resilience of the tyre walls.

(*PhD candidate Yachong Xu, Principle Supervisor Associate Professor Yan Zhuge, Co-supervisors Dr Reza Hassanli, Dr Mizanur Rahman & Dr Martin Freney)

Dr Freney's PhD Research

Martin Freney's PhD thesis is titled Earthship Architecture: post occupancy evaluation, thermal performance and life cycle assessment. (2014)

It compares the Earthship's curious features such as the off-grid systems, tyre walls and the greenhouse (sun-room) to other types of homes in terms of sustainability. Essentially the research questions was:

How "green" is the Earthship compared to other types of housing? And why?

Three main issues were studied:

The main findings were:

It compares the Earthship's curious features such as the off-grid systems, tyre walls and the greenhouse (sun-room) to other types of homes in terms of sustainability. Essentially the research questions was:

How "green" is the Earthship compared to other types of housing? And why?

Three main issues were studied:

- Life Cycle Assessment - this looks at the environmental impacts throughout the life cycle of the home (construction phase, occupancy phase and demolition phase). The types and quantities of materials used to build an Earthship, and other types of homes, were catalogues and analysied in terms of how damage is done to the environment due to the materials and energy used throughout the life of the various homes.

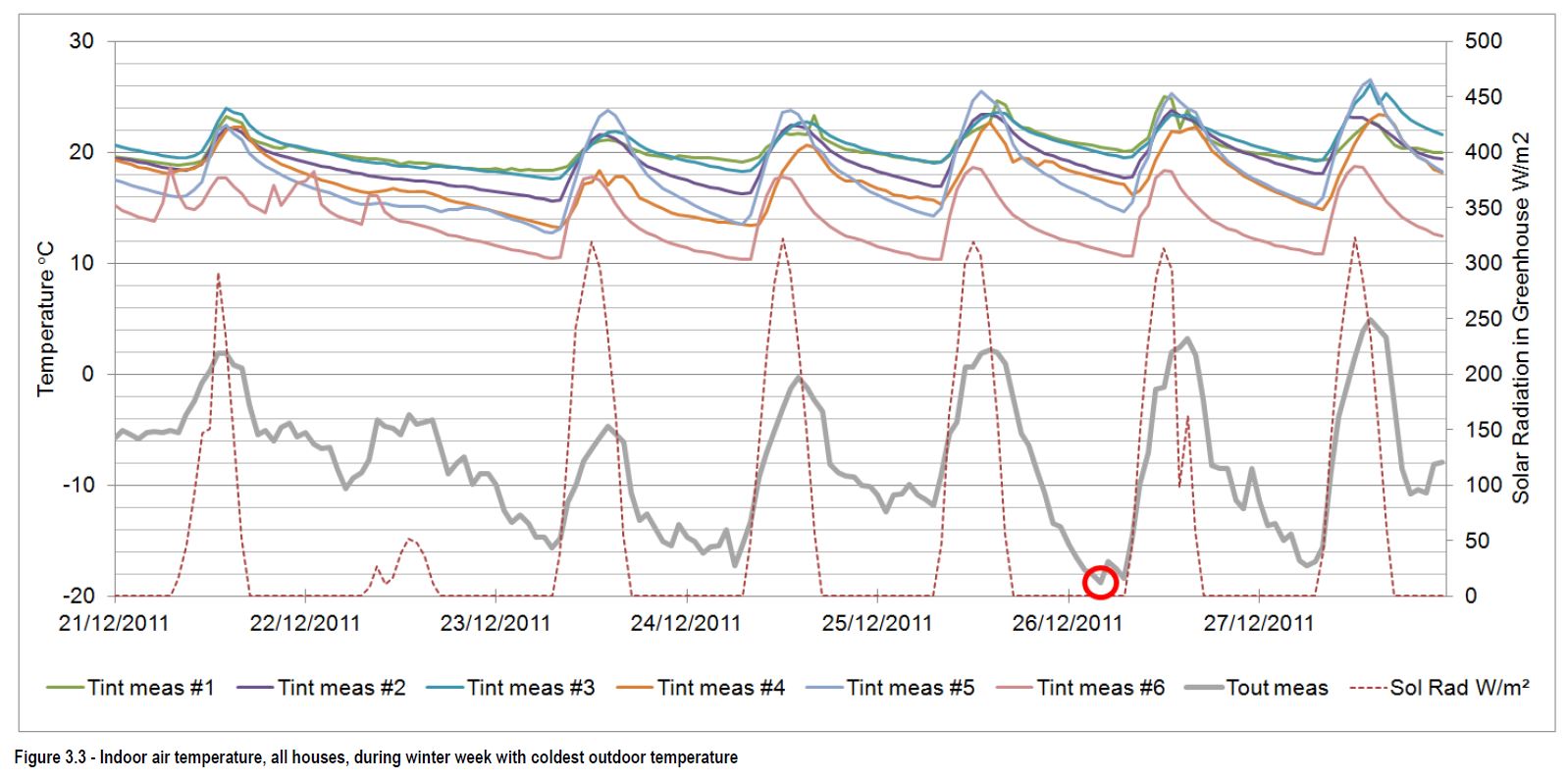

- Thermal Performance - this involved measuring the outdoor and indoor temperature (and humidity) of six Earthships, of different designs, all at the same location (same climate) in the USA and developing a computer model that could predict the performance of an Earthship in different climates. A major focus was the role of the tyre wall, the earth berm and the greenhouse on the thermal performance of the Earthship and this was compared to the thermal performance of other houses made from other wall construction materials such as straw bale, rammed earth, mud brick, brick veneer, double brick etc.

- Post Occupancy Evaluation - this involved interviewing people who had lived in Earthships for many years; asking them about their experiences with the Earthship's off-grid systems and, in particular, asking them about the comfort levels inside their Earthship.

The main findings were:

- Life Cycle Assessment - over the life of the Earthship it is the off-grid systems that are most important in terms of reducing environmental impacts. Natural and recycled construction materials help, but the energy and water saved over the life of the Earthship due to its excellent thermal performance and water recycling systems are the most significant.

- Thermal Performance - an interesting finding was that the greenhouse of an Earthship is at its hottest during the winter, not the summer as many people incorrectly guess! This is because of the low winter sun which "blasts" the Earthship with solar energy, whereas in the summer, the high summer sun "bounces" off the greenhouse windows (which are double glazed). The earthtubes, indoor garden and thermally massive floors and interior walls also mitigate any overheating potential in the summer. Furthermore, the modern Earthship designs performed significantly better than the older models, maintaining relatively stable indoor temperatures despite extreme outdoor temperatures - see the graph below.

- Post Occupancy Evaluation - Earthship occupants enjoyed living off-grid and being involved in operating (or "sailing") their Earthship's off-grid systems. They reported comfortable indoor conditions (temperature and humidity) for the vast majority of the time and felt that their choice to live in an Earthship was: less damaging to the environment, less expensive, more comfortable, more relaxed, more enjoyable and more healthy.

The graph above shows the indoor temperature inside six Earthships in Taos, New Mexico USA during the winter week with the lowest temperature (circled in red). The bold grey line is the outdoor temperature and you can see it is sub-zero most of the time, day and night. However, all the Earthships stay well above 10 degrees C, and many of the modern designs (#1, #2, #3) remained above 16C. Earthship #1 stayed above 18C! This is with NO HEATER! Only Earthship #6 had a heater which you can see turning on and off on the first two days of the week. The dotted red line is the sunshine... day 2 (22/12/2011) was a cloudy day, and it is interesting to note how all the Earthships behave - they all lose temperature... but some more than others! Design AND how you "sail" your Earthship are key factors.

Click here to download a PDF file of Freney's PhD thesis titled "Earthship Architecture: post occupancy evaluation, thermal performance and life cycle assessment".